Plated Tungsten Alloy Tubing

Any question about this product, please email sales@sjpec.com. You will get reply within 24 hours!

Key Features

- High combination ability

- High-temperature resistance

- No flake or pollution

- Advanced nickel-based technology

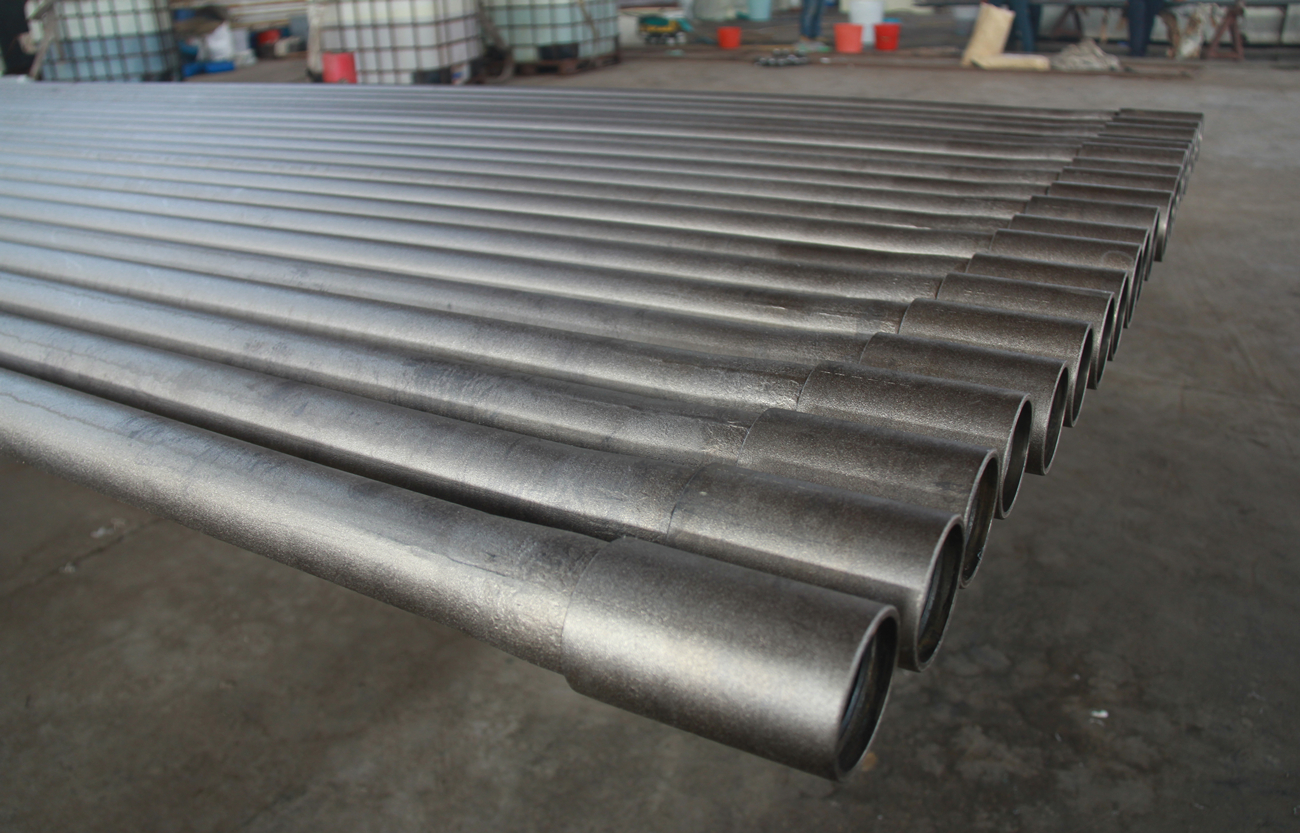

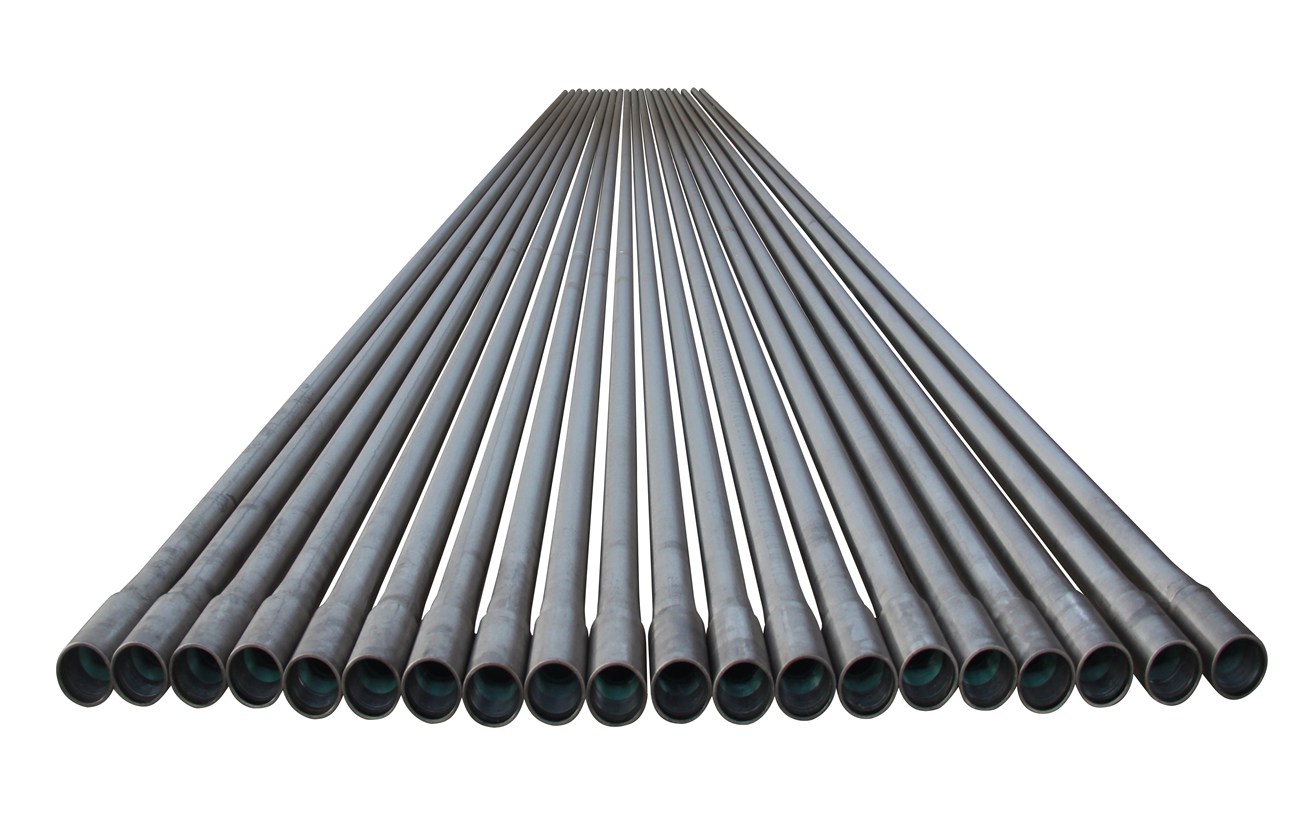

Plated Tungsten Alloy Tubing

Due to the strong carcinogenicity and severe environmental of hexavalent chromium ions, the use of chrome plating technology in China has been gradually limited, and some products have been limited by the two directives, WEEE and ROHS from EU.

Therefore, the new environmentally friendly substitution of chromium technology R & D draws more and more attention. And as a new substitution of chromium technology, tungsten alloy plating process, due to its special structure as well as good wear resistance and corrosion resistance, has been gradually focused on by people.

And in the field of petroleum machinery, it has been popularized and gradually recognized by customers because of its excellent corrosion resistance (resistance to chloride ions, hydrogen sulfide).

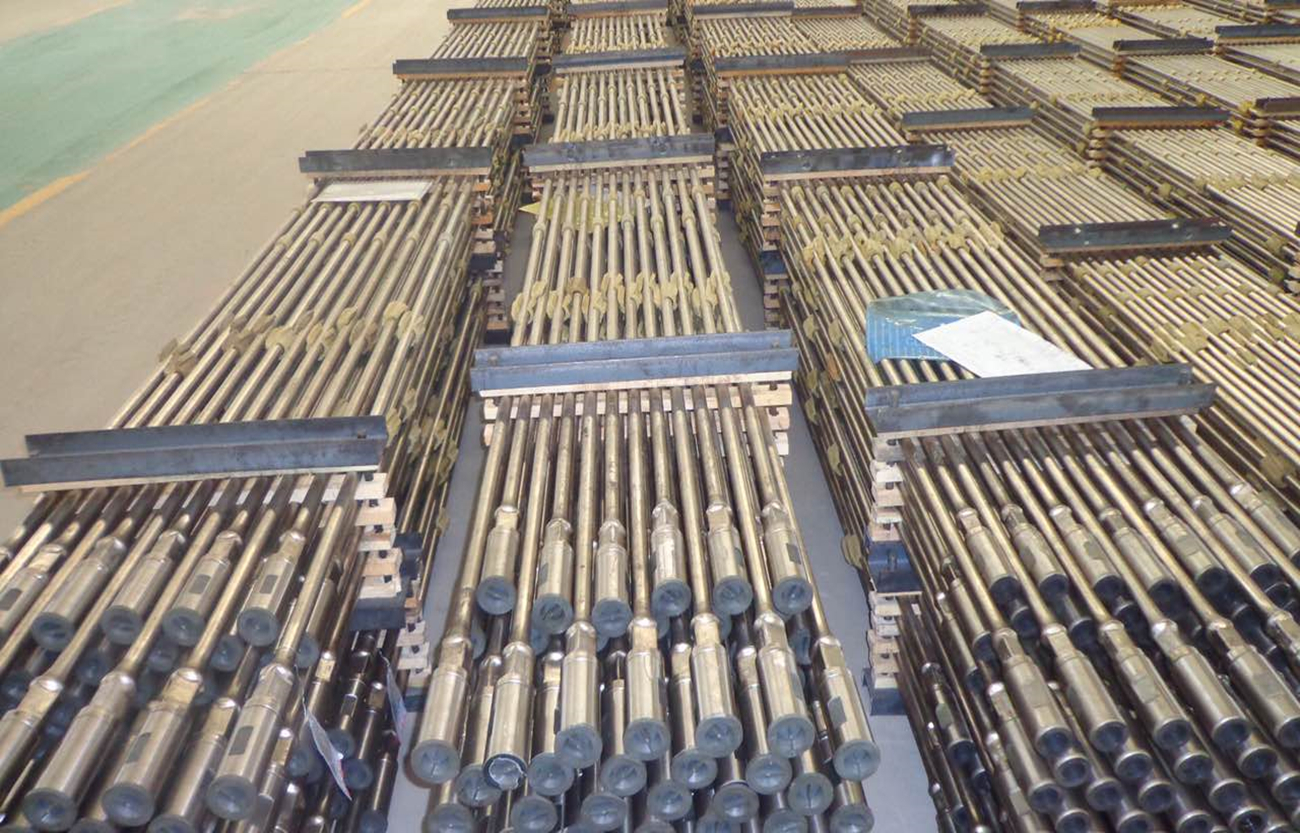

For example, electroplating tungsten alloy anti-corrosion tubing and anti-corrosion sucker rod have been in a mass application in the oil field with its good condition.

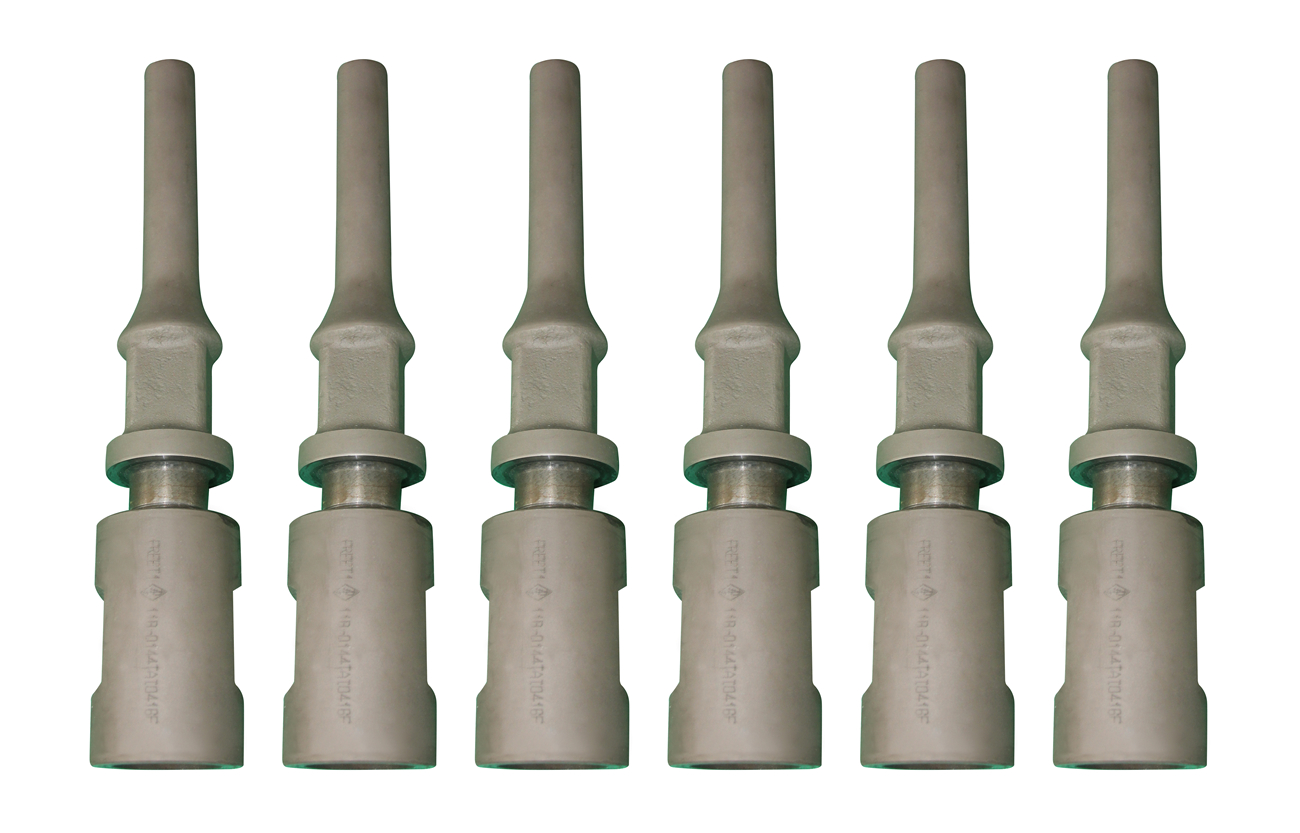

But the wear resistance of tungsten alloy is lower than that of electroplated chrome layer when tungsten alloy has been applied in the PDM drill, oil pump barrel, and other products.

We Shengji have been going for extra miles in R & D of tungsten plating, and thus we can improve anti-abrasion performance, low the porosity and, promote the protective performance of plating on substrate Besides, the new technology has successfully been used in tubing, steel barrel, PDM drill, sucker rod, copper pump barrel products, meanwhile all aspects of performance indicators have been taken by international customers.

|

Item |

Parameter |

| Plating composition |

|

|

Plating hardness |

50-550HV (plated state), 940-1100HV (heat treatment) |

|

Wear resistance |

2-3 times better than chromium plating |

| Corrosion resistance |

resistance to aggressive service like H2S, CO2, NaCI, HCI, etc. |

|

Current efficiency |

80% -85% |

| Deposition rate |

35um-45um / h |

|

Adhesion |

8Kg/mm2, plating no falling under high temperature and pressure. |

- Environmentally friendly technology for plating, no wastewater containing heavy metal ions and recyclable plating solution;

- High adhesion regardless of well depth and temperature;

- Excellent performance of resistance to abrasion and corrosion (for anti-abrasion, 2-3 times better than chrome plating, and strong resistance to chloride ion and H2S);

- Antioxidant and anti-aging for many times using;

- Little impact on tubing ID because of 30 um or so of plating thickness generally.